neoOberon

Members-

Posts

48 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Newfoundland, Canada

-

Woodworking Interests

Hand Tools, Not Losing Fingers

neoOberon's Achievements

Apprentice Poster (1/3)

5

Reputation

-

There were no sparks...a metal blade (band saw or a cold cut saw (circ saw for metal)) do not create sparks. If it were an abrasion disc, then sparks aplenty.

-

Patricks Blood and Gore strikes again...hope to god that page never goes down. Click the link and scroll to the bottom...a little read about your new tool. http://www.supertool.com/StanleyBG/stan9.htm

-

Wow...although I don't know you, I feel bad for you. Usually I'll have a bone-head moment at least once per project. Once I was cutting something with my Milwaukee cordless circ saw; the material was locked in my JawHorse. Like yourself, I got so far and thought "why is this so hard to push though". Stopped and saw I added a "speed hole" to my JawHorse. Luckily it was my cordless and not my 15amp corded...damage would have been worse.

-

Curiosity on my part...will you be using only the floating tenons (Domino's)? Meaning, one end in the 1x6, the other in the 3x3? Eric, gorgeous bed...

-

As everyone else stated, LED's are the way to go. Even if you vent for xenon, it'll still be hotter than LED's. The excess heat will dry out your wood, may cause warping and is a potential fire hazard down the road. I'm not an expert, just my two cents....

-

Cleaning a new cast iron table saw

neoOberon replied to avion2001's topic in General Woodworking Talk

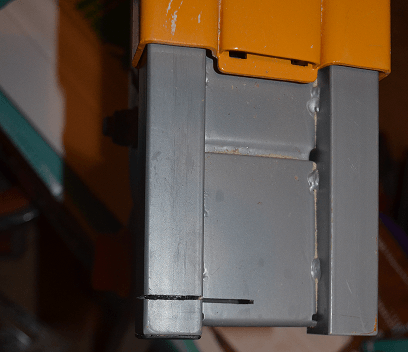

I hear nothing but good things about Boeshield T-9. Since Boesheild isn't readily available here, I went with Fluid Film. Since Fluid Flim doesn't dry out, probably not suitable for a table saw used in "fine" wood working. Below is a pic from a independent lab test... That being said, I used FF on my portable table saw...as luck would have it, there was a leak in the garage and my saw was the "bucket" catching all the water. Short story shorter; I have no idea how long the leak was there, but my saw is still rust free. And that says a lot since I live in Newfoundland, Canada. Rust here is a fact of life...I've been to the nut house and back trying to prevent rust. I can honestly say, I probably hate rust more than everyone here combined... https://youtu.be/sTP7f6t8CGk Edit: I just pulled this from Fluid Films website...maybe it would be ok for your table saw. Does FLUID FILM attract dirt? Because FLUID FILM remains wet, it will get an initial dusting upon application, but because it contains no solvents and will not become sticky, it will not gum up or create a build up of dirt. Second Edit: Further down it says this...so maybe the film will transfer to the wood and cause issues when finishing. Does FLUID FILM dry out? No. FLUID FILM is a lanolin based product containing no solvents. It will not evaporate or dry from the surface. FLUID FILM will leave a wet, non-drying film, that will provide long term corrosion protection on all metals and superior lubrication for all moving parts. Best just to reference the Ferrari line. It's a saw, not a dining table from Louis the XIV palace. Or just replace the cast iron top with granite. Sorry, I was zero help...if it didn't take me so long to compile my post, I would just delete it. -

I bought SB pads at home depot...the same section I bought Steel Wool from. I can't remember the colours available, but I bought green, gray and blue (looks blue to me). The ones I bought are more a "sponge" than a sheet of sand paper. I assume they're close enough...just a different "format".

-

I bought a new DMT diamond stone (Extra Coarse)…out of the box it has a 1″ hairline scratch on one end. Disclaimer: this is my first sharpening stone. Will this affect my blades when I sharpen them? I will be using the stone with a Veritas MKII honing jig. If I orientate the stone one way, the blade won’t see the scratch. However if I use the stone that way, I would imagine it will wear unevenly. Just looking for some input…should I keep the stone or return it? I've contacted DMT customer service; no response yet. Thx, Chris

-

Thanks everyone for the feedback...looks like this will be my joint of choice for plywood projects.

-

My jointer is a No. 7 vintage Stanley (Bailey). Whiteside it is...I've never heard of Whiteside, but searching the forum and online, they appear to have quite the following. Thanks everyone for the input...

-

I don't have a router table...and for the amount of us it would get, I'm not looking to build one. So my router will be used by hand. The reason for rabbit/dado bits is because of setup...I'm primarily a hand tool user, so I don't have a big power tool setup. I wanted to make some basic cabinets and maybe a bookshelf or two. If I were to cut rabbits in the end of a 8ft section of plywood, I can see things getting out of hand. Cutting length wise shouldn't be a problem...but again trying to slide a 6ft/8ft length of plywood sideways probably won't end well. I could use hand tools I guess...router plane and a carcass saw. If I were to use a table saw, I assuming I would need to build a dado sled? Seriously, I have no idea...

-

I'm looking to buy a Rabbiting Bit for my router...will primarily be used on sheet-goods. I'm looking to go with a 1/2" shank... I've seem some bits come with a few bearings, where as others come with 6-7...do I need a lot of bearings? I'd rather pay extra and get a good bit...if Frued good? Or is Frued over-rated? Also, can anyone recommend a dado bit...again, primarily used with sheet-goods. I'm ordering a Dado stack for my saw...but need the versatility of the router for some projects.

-

What did you use to cut it? Dado stack or a router? (both?)

-

New framing square! One time Tool.

neoOberon replied to wdwerker's topic in General Woodworking Talk

I have to ask...wouldn't Woodpeckers T-square be better at sheet good layout than a square? I ask because I'm new... -

I'm doing the ground work for building plywood boxes (cabinetry and bookcases). I'm was intending to use rabbits for the joinery... However this just caught my eye...maybe this is the way to go. It's labeled a finger joint, but not what I would typically call a finger joint (I'm new, what do I know?). Just wondering what other people use...is there a consensus on what joint is best for my application.