Kranzpj

Members-

Posts

42 -

Joined

-

Last visited

About Kranzpj

- Birthday July 24

Profile Information

-

Gender

Male

-

Location

Robbinsville, NJ

-

Woodworking Interests

Ramping up a workshop, stand alone pieces

Kranzpj's Achievements

Apprentice Poster (1/3)

2

Reputation

-

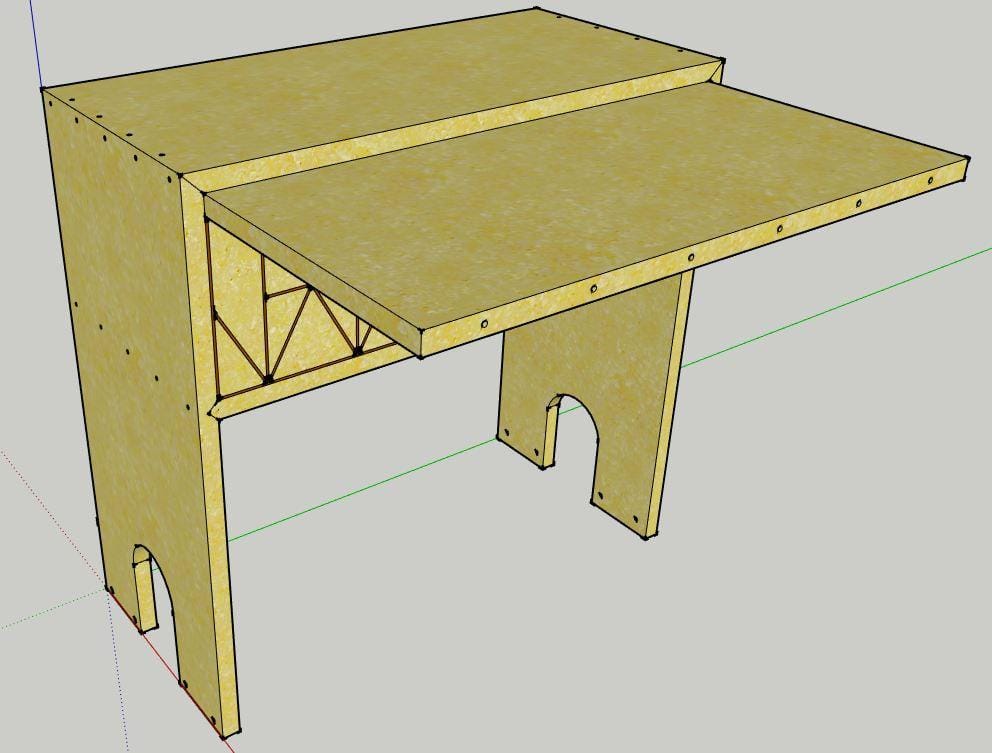

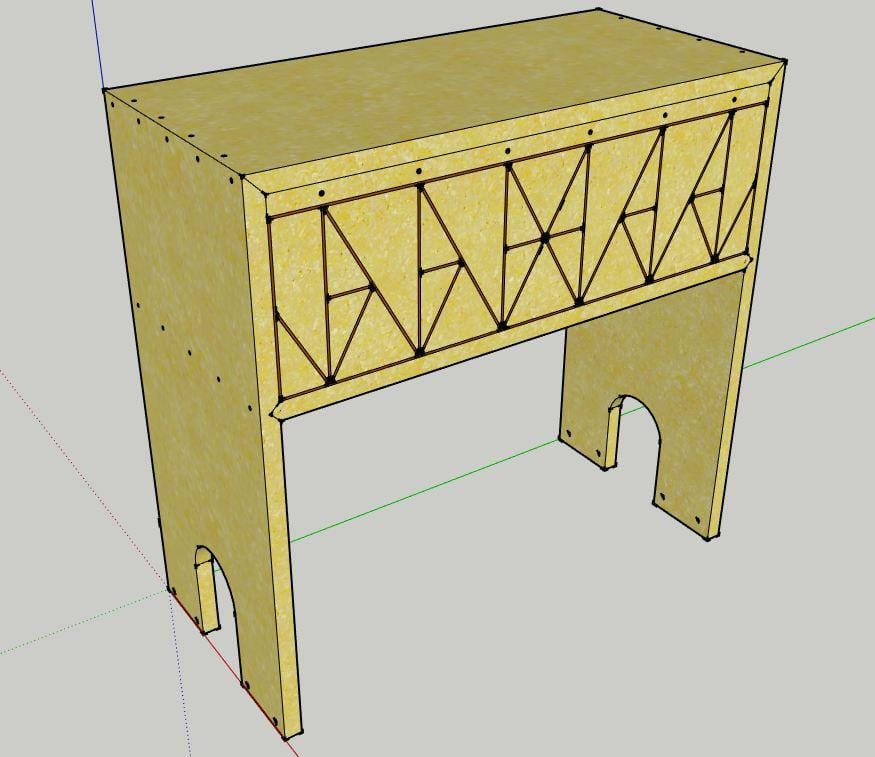

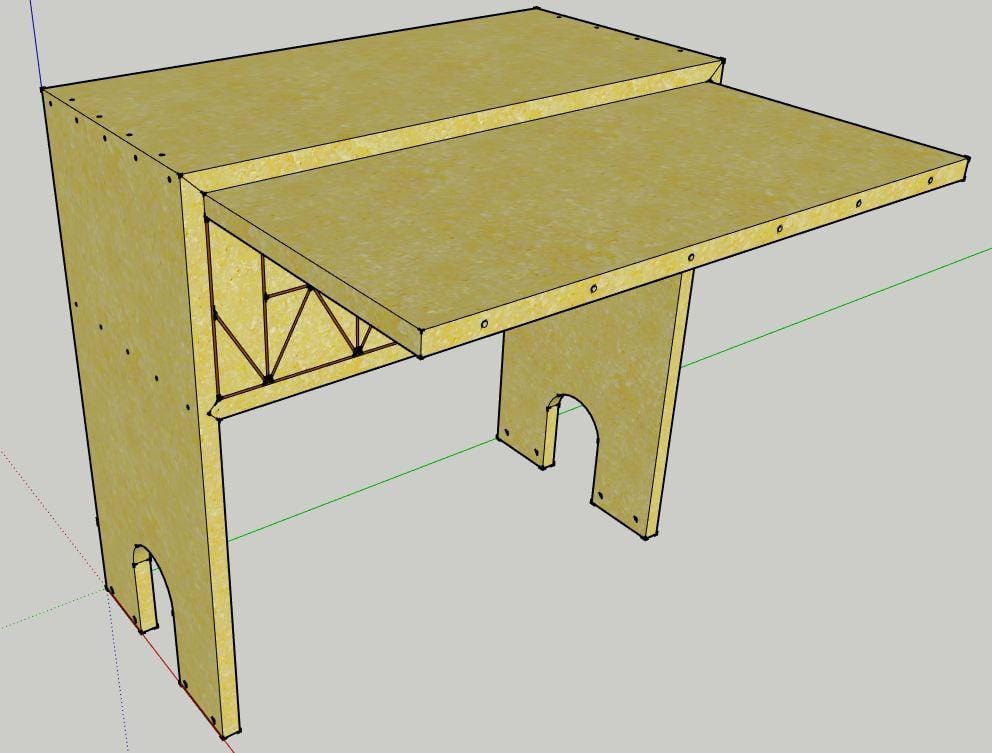

I'm designing an entertainment center / desk. Our 32" TV is hooked up to a Mac Mini, so it doubles as a TV and a computer monitor. The picture should help here, but I'm looking for some type of drawer slides that will support a 32" x 18" work surface. I have found several 18" drawer slides, but none of them are rated for anywhere close to a 32" long panel. Any ideas?

-

I know I should get a separator for my HF DC + Wynn 35A filter, but in the meantime I'm looking for a way to efficiently clean the filter. The primary suggestion seems to be hitting it with compressed air. I don't currently have an air compressor and while $60 and a trip to HF should take of that, is there anything else I can use the air compressor for? I don't use many brads, staples, or any fasteners for that matter. And I believe I'll need a proper HVLP system if I branch out into spray finishing. I seems a shame to spend $60 to clean a $180 filter. Any ideas?

-

I can give that a try, I guess I've been trying to flatten the first 2.5" so far.

-

I recently purchase a set of inexpensive Narex bench chisels and I've trying to several hours to flatten the backs with mixed results. 2 of the 6 are flat (I've used a sharpie to judge), but other 4 have various high spots, some at the tip, the 1" chisel still has a quarter-sized high spot in the middle. And despite hundreds of strokes I don't seem to be getting any further with 220. Setup: I've been using a 220 equivalent DMT 8" diamond plate and some water. I have the 325, 600, and 1200 equivalents, but I haven't gotten there yet. Method: I've been holding the blade perpendicular to the stone with as much of the blade as possible on the stone and moving back and forth along the length of the stone staying perpendicular to the stone. For the 1/8" chisel I held the chisel more at 45 degrees for a larger reference surface. I did try to run one chisel on some cheap 180 sandpaper on my MDF workbench, but it only trimmed the edges of the blade and now it's convex. Go I need to go scary sharp down to 180? (I'd hate to buy nice sandpaper and a flat surface for what should be a one-time operation) If so, what is the most efficient movement to flatten the back? Or is there a better method for use on the 220 diamond plate? Thanks

-

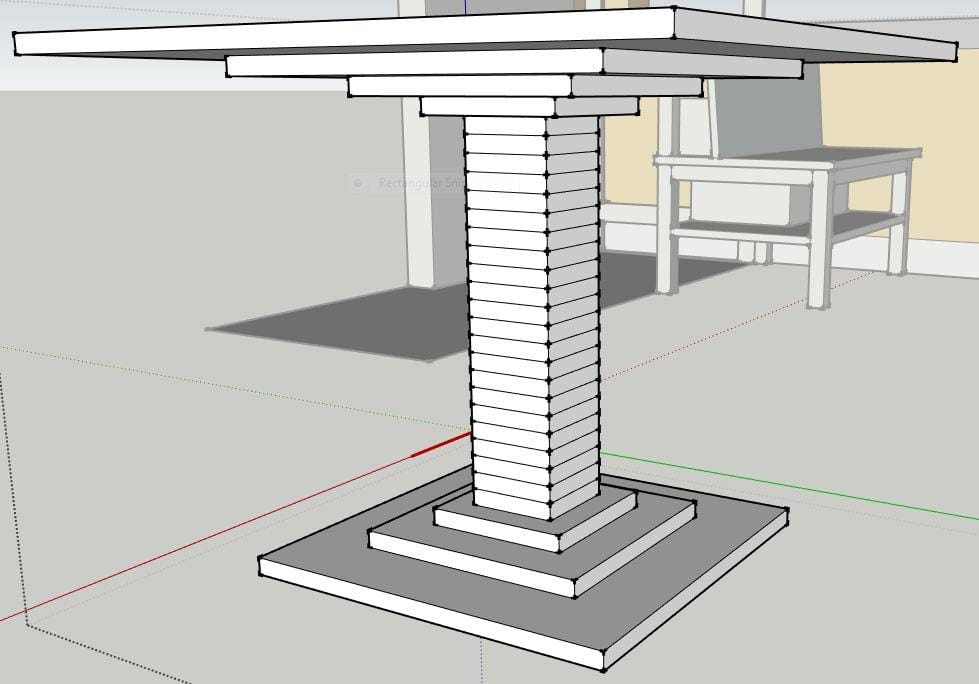

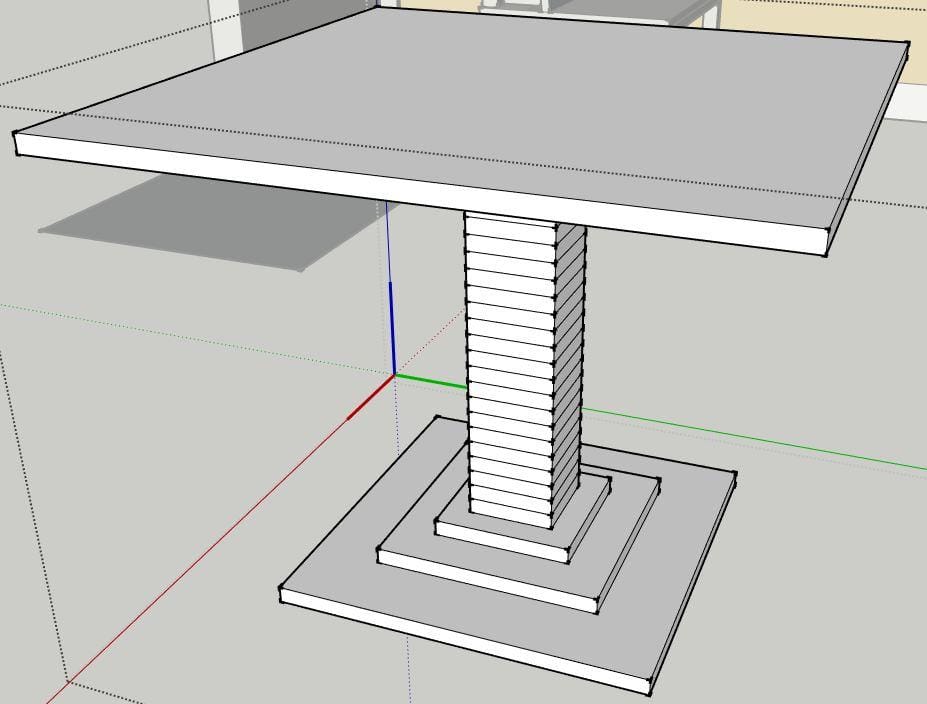

Design Guidelines for Square Pedestal Table?

Kranzpj replied to Kranzpj's topic in General Woodworking Talk

I was thinking about something a little more radical and have the entire pedestal made up of 5x5x1 boards oriented horizontally and glued up layer by layer. Maybe I'll alternate the end grain and side grain. -

I'm designing a small, square pedestal table with a tabletop of 36"x36". I have a couple questions: - How wide should the base of pedestal be in order to prevent tipping? The one in my sketch is about 22"x22". - Do I need to put cleats beneath my tabletop? considering I'm putting another 22"x22" panel supporting the table (see pic)?

-

Second thought, looks like the "stones" are only 2" wide. Probably too narrow for a 2-1/4" jack plane blade.

-

I like the all diamond idea. It seems like less mess and no flattening. I can see falling into the trap of getting too precious with flatness. Maybe the DMT 3 Whetstone is a good start. Best Amazon rating I've seen for a woodworking item: http://www.amazon.com/DMT-W6EFC-6-Inch-Diamond-Whetstone/dp/B003NCVFC4/ref=cm_cr_pr_product_top Maybe if I want to get fancy later I can add the 8000 grit equivalent diamond bench stone: http://www.dmtonlinestore.com/8-Dia-Sharp-Continuous-Diamond-Bench-Stone-P15.aspx

-

I'm planning to get my first hand plane for Christmas and have been researching sharpening systems. I'm looking for something quick, foolproof, and relatively inexpensive. I seem to be leaning toward the M-power sharpening system. (http://www.m-powertools.com/products/pss1/pss1.htm). It seems inexpensive when compared to waterstones and a honing guide, and I'm assuming since we're talking about diamond plates they don't need to be flattened. I'm also guessing you can use the same plates to flatten the back freehand. Anyone have experience with this system?

-

Thanks all!

-

Despite my best effort I sometimes will dab my forearms with poly during application (or have it seep through my latex gloves). Is it safe to dab a little bit of mineral spirits on the spot and them use soap and water?

-

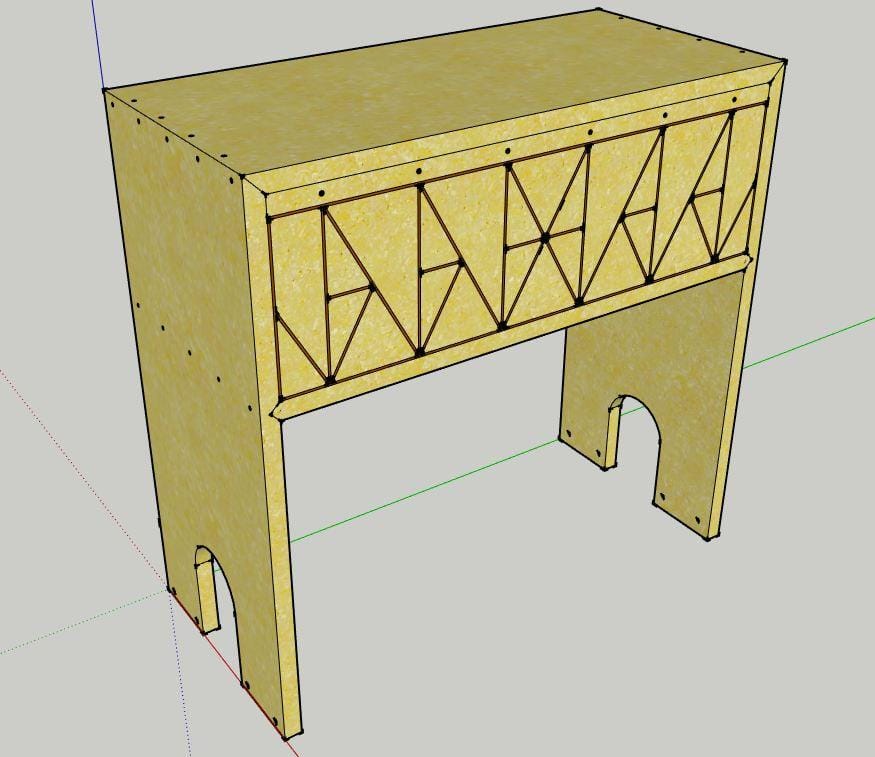

Design Review for Entertainment Center / Desk

Kranzpj replied to Kranzpj's topic in Project Journals

I'm considering getting the Woodpecker boxclamps and hoping those can hold the miter together during the gluing, drilling, and peg pounding. -

Design Review for Entertainment Center / Desk

Kranzpj replied to Kranzpj's topic in Project Journals

I was thinking about undermount drawer slides. -

Design Review for Entertainment Center / Desk

Kranzpj replied to Kranzpj's topic in Project Journals

31" H x 32" L x 15" D. Maybe anchoring it to the wall is a best practice regardless of the desktop, considering we have a toddler. -

There isn't a design section, so maybe this is the place for this. I'm designing an entertainment center/desk and am looking for some input. It will support a 32" TV that doubles as a monitor for a MacMini. There is a 1 inch board directly below the top of the case that will pull out to support the keyboard and other desk paraphenalia. There isn't a ton of storage, but in the post-CD, post-DVD era we don't really have much to store aside from the Mac, and an external hard drive. Design motifs - I've based the design off the Queensboro Bridge in NYC. We used to live in an apartment overlooking the bridge. - I've simplified the geometic pattern of the bridges trusses on the drawer front. - I've used pegs throughout inspired by the bridge's rivets - The arches in the legs are similar to those in the base of the bridge Questions: 1. I've used "pegged miters" for top case joints. I've never seen this used before. Think it's stable enought for a 32" TV? 2. The TV will be putting quite a bit of weight on the base, but do you think tipping will be a problem with a little weight on the keyboard tray? Thanks Paul