-

Posts

426 -

Joined

-

Last visited

JoshC1501's Achievements

Journeyman Poster (2/3)

98

Reputation

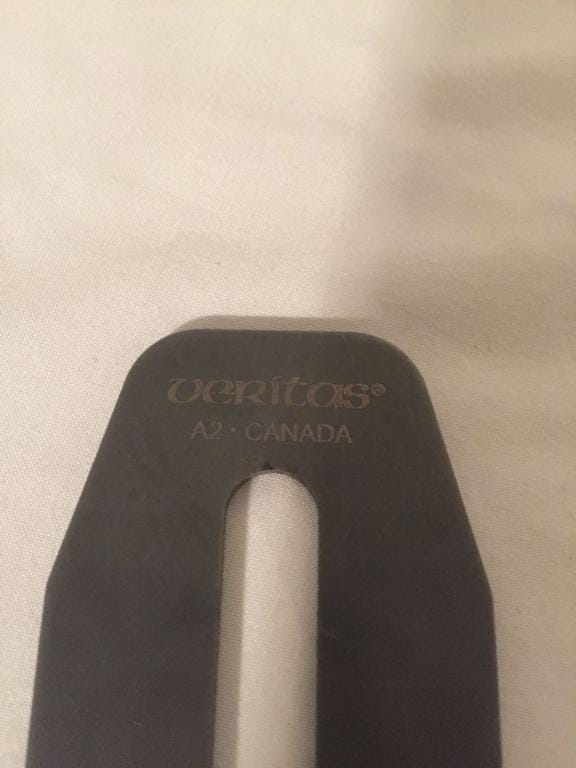

-

I acquired this with some other tools and lumber in one big lot. The original owner bought it and never got around to using it. 175 + shipping charges. Message me if interested Josh

-

Laguna bandsaw blades I don't like you

JoshC1501 replied to Tom Cancelleri's topic in General Woodworking Talk

I resaw a lot of wood with my 1/2" woodslicer, and they last a long while. They are great all around blades too. I use mine for most all my bandsaw work. The lower cost general purpose blades highland sells are also good and resaw pretty well. They just don't last as long. -

I purchased these from Patrick Leach awhile back, and never touched them. You will get them in the exact condition I received them in and Patrick only sells top quality used tools. I bought them with the best of intentions of using them, but never got around to it and probably never will. I gave $85 for them, would like to get $75 Josh

-

Price is in the subject $300

-

-

I am selling my Lie-Nielsen Low Angle Jointer 7 1/2. I purchased it new about a year ago. There is nothing wrong with it, it has been used and shows normal signs of wear. There are a few minor dings on the top of the handle. I am only selling because I like BD planes better so I bought a LN #7. It is sharp and ready to work.

-

I picked up an item today I am looking for help identifying and trying to figure out what it's worth and who might have a need for it. I have a long standing habit, usually a profitable one :), of picking stuff. It's fun!! This huge and heavy piece of steel is 24"x36"x7/8". It has a 36" starrett rule inlaid in it. The top 1/4" or so appears to be a different material/layer. It's steel but it has a fine grooves running across it, not only the ones u see in the pic but very fine grooves that cover the whole surface. Searched online but couldn't find anything like it. The guy I got from pulled it out of a machine shop from an old factory, that is all I know about it. This is what it was mounted on, only 1/2 ply and some machine screws holding it up! The ply kind of tore apart when we moved it. Would appreciate any help I could get, even if it is pointing me in the right direction. Josh.

-

I have not, but did some research on how to do it. That is exactly what I did. It has three different nicker lengths, the shortest extends below the bottom of the plane about a 1/16". On softwood it works "ok" on hardwood it is a show stopper. Either it is to long, or it needs to be sharper than it is? Thoughts? Josh

-

Thanks everyone. Got it all put back together today, and it works pretty well. I kind of feel like the nicker protrudes down to far, it is difficult to get the iron to engage when using the nicker. It sort of rocks on the nicker. Since it has 3 sides, thinking I would file one down a little and see if it works better. Tom, thanks for the help but I found it complete. I just had the nicker out for cleaning.

-

I would like to be able to cut rabbets with it.

-

Hello everybody, its been awhile. I have been lurking, just not posting much. Too busy building things in the shop!! I picked up Craftsman(Sargent made) Rabbet Plane a couple weeks ago for a nice price at a local antique store. I paid $20 for it, and 100% complete, first time I have found one complete. Started working to get it tuned up and ran into a few issues. I would appreciate some input. The bottom flattened pretty quickly, there is decent sized shallow area on the side opposite the main reference face. Curious if this will be an issue? I figured since the bottom is 95%+ flat and the shallow area is opposite the main reference face, then it would be no problem. When I started to lap the side reference face, it become apparent really quickly that It had some major problems up near the toe. See the attached pic. Starting just behind the blade is shallow area of around .004" and that continues up from the nicker to the opening for the bullnose. After the bull nose though the shallow area is .008" near the bottom. It extends up about an 1 1/2" My question is, with a plane of this type how flat is flat enough? Do I need this whole side dead flat, or will these shallow areas not effect use? I could probably spend the time to get most of the shallow up to the bullnose mouth, but .008" is a lot of steel to remove, and I am not sure I am willing to put in that sort of time to get the whole side flat. Appreciate any input I can get. Thanks in advance! Josh

-

I have a list of tools I want to buy, mostly of hand tools but some power tool stuff as well, either save it for the next one on the list or buy it.

-

Thanks guys!

-

Any thoughts on using this joint without screws and ebony plugs? If the joint doesn't see a lot of abuse will it hold well with glue only? I have Never made this joint, but thinking about using them on a small box type project. Don't want any plugs or fasteners but looking for something quicker than dovetails.

-

Oil/Varnish blend