-

Posts

133 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Massachusetts

-

Woodworking Interests

hobby

pagel's Achievements

Apprentice Poster (1/3)

5

Reputation

-

There are quite a few track-saw and track-saw-like gizmos out there. I would go with building your own as Beechwood Chip suggests...easy and cheap to make. But if you're looking for something that actually tracks your saw, you can find a very cheap alternative here - http://www.justclamps.com/edge_clamps_guide-Plates.htm. I bought this setup for making crosscuts (no tablesaw) and it's worked fine so far - attaching it to my saw was a PITA. It's a plastic plate thingamajig that runs along an aluminum extruded edge guide/clamp (not included with plate). I'm not sure how long it will last given the plastic, but when it does fail I'll have gotten more out of it than what I paid. Disclaimer: my recommendation is not based on quality per se but on bang for buck. If you can afford the more expensive systems, go for it.

-

I have a Starrett double square and love it, but you might want to consider PEC as an alternative if you're on a budget. It's sometimes thought of as the next best compared to Starrett. Phil Lowe recently did a "tool test" of combo squares for FWW and ranked the PEC as the best value. They also found that "...double square models sold under the brand names PEC, Lee Valley, Brown & Sharpe, Pinnacle, and Mitutoyo all appear[ed] to have been made by PEC" with PEC usually being the cheapest of the lot. Here's a 4" PEC double square for about $27 on Amazon - http://www.amazon.co...53640732&sr=1-3 Or even a better price at $22 at wttool.com - http://www.wttool.com/index/page/product/product_id/17789/category_id/17557/product_name/Double+Head+Square+Sets+%28PEC+Tools%29

-

For me it's on the basis of need. I usually get "new" tools when I need them for a project. That hasn't always been the case but with a few exceptions I use all my tools more or less. The other thing that keeps me from going nuts on tools is limited space. If I had Marc's new shop, I'd be in trouble.

-

No one wants custom cabinets anymore.

pagel replied to Jeremy Smith's topic in General Woodworking Talk

The economy is actually doing quite well. Of course it depends on where you fall along the economic scale. Wealth in fact has been increasing....but into fewer and fewer hands. Nearly all economists are in agreement about these trends, which have been in effect for quite some time, they just disagree about whether the resulting disparity is a good or bad thing. This is simply to say that the segment of the population your father and grandfather relied upon as clients has dramatically changed. Either they can no longer afford the level of custom cabinet work your family has traditionally provided or they choose not to afford that type of custom work. It's probably a bit of both, but I suspect the latter is more at play here. Regardless, it's all part of the same trend that is trading off on uncertainty despite gains. The situation Paul describes reflects this trend. It highlights a radical shift in investment strategy as a result of the 2008 collapse. It's not that the wealthy can't afford x, y, or z - they can! - it's that they've chosen not to spend as they once did in part because their wealth is not as fluid as it once was, but more importantly because they're protecting that wealth - hence, shifting investment strategies that lead to the fact that their wealth is not as fluid as it once was. So yes "it's the economy stupid" but not necessarily as we think. Not so ironically, we're seeing the same sort of shifts within the professional woodworking food chain. Who has the resources and ability (reputation and clientele) to weather the storm? I predict the "high-end artisans" that Paul mentions will weather the storm just fine... -

Likewise... I also was wondering about Don's absence and hoping all is well. We miss ya dude!

-

Me too... I'm just up the road in the Northampton area and pay around $5 a board foot for Maple locally.

-

Another thumbs up for Bell Forest. I've used them several times for relatively small orders and have always been pleased. It's also nice getting that follow up email from Corey.

-

I agree with Ends of the World regarding riser blocks. If you need that extra capacity for resawing and expect doing a fair amount of it, you'd be better off investing in a larger BS now rather than later. On the other hand, I think most people who anticipate doing a bunch of resawing before bumping up against that need actually find themselves doing far less of it than they thought. In other words, you'll probably find that a 14" will be more than enough capacity to adequately serve your needs for quite some time.

-

How much do you have or are willing to spend? There's quite a range of bench vises in terms of quality and price. I would not recommend the uber-cheap ones, the savings are not worth the hassles, but you don't necessarily need a $100+ vise either. Addition: you might also look at John White's New Fangled Wookbench to get some ideas on alternmative ways to clamp and secure stock to a bench. It's a very versatile bench design that doesn't break the bank. Here's a link to the video - http://www.finewoodworking.com/Workshop/WorkshopArticle.aspx?id=28530

-

Same here. It works great with my 2hp DC as well.

-

Workbench Plans - What do you think?

pagel replied to ReLMAustin's topic in General Woodworking Talk

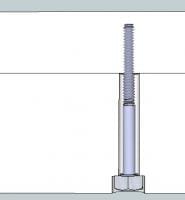

You should be fine with the 2" top for holdfasts. The Grammercy holdfasts, for example, require a minimum of 1 3/4" thickness to work. As far as attaching the top, you want to allow for movement in the top. The illustration below is what I think Schwarz meant when they used larger diameter holes in the rear of the bench to allow for that movement, i.e., the holes in the top stretchers - not the benchtop. However, as Onboard points out, you would need to adjust for the thinner top and I agree that a 2" top for this type of bench is on the thinish side. Note: the bolt is obviously not a lag bolt but you get the idea -

I didn't even know this was available! So you didn't experience any movement in the fence while planing? I've goitta try one of these. Thanks, pug!

-

Okay, the Maple jaw is far too tall for the vise - too much material above the metal face of the vise. As a result, it's racking. I would remove at least 3 inches off the top so it looks closer to this (below), which will necessitate moving the entire tailvise up along your apron to keep the jaw flush with the top of your bench. If you could post an image of your tailvise, that would also help in diagnosing the problem.

-

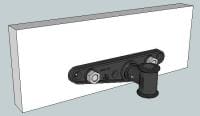

I'm trying to envision what the face of your tailvise looks like. Given your dimensions, is this an accurate representation?